...

Default priority: If this is set as blank, the priority on the jobs will automatically be set on the basis of the asset’s criticality, i.e. A=1, B=2, C=3 and D=3.

Memory Limit [PHP]: By default set By default set to 128 MB. Used during import.

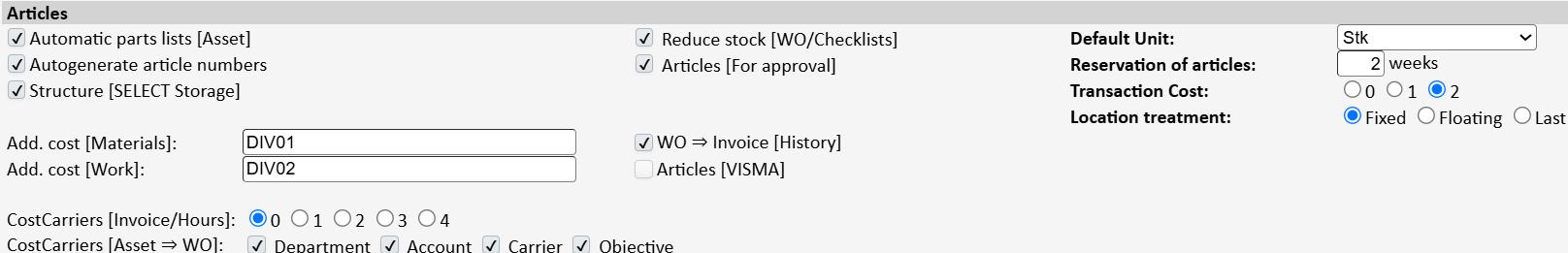

Articles

Automatic parts list [Asset]: If Do not allow negative stock: If this is activated, it will not be possible to make negative withdrawals from inventory.

Reduce stock [WO/Checklists]: If this is activated, by default, on approval, ‘Reduce stock’ will be checked on the approval screen. Note that this setting does not affect the automatic stock draw when approving a checklist where the unit at the lubrication point has the same unit as the article connected to the lubrication point. Here, it is deducted from the storage regardless of whether it is activated or not.

Automatic parts list [Asset]: If this is activated, parts that are used on the work order are automatically added to the parts list of the asset, if the part is not already there.

Autogenerate article numbers: If this is activated, an article number is taken out in accordance with the selected/allocated meter under the menu point ‘System’ → 'Miscellaneous system settings’.

Structure [SELECT Storage]: If this is activated, the storage structure is displayed in the selections where stock is selected. For example. under ‘Articles’. Activate, for better viewing, if you have a deep storage structure.

...

parts that are used on the work order are automatically added to the parts list of the asset, if the part is not already there.

Autogenerate article numbers: If this is activated, an article number is taken out in accordance with the selected/allocated meter under the menu point ‘System’ → 'Miscellaneous system settings’.

Structure [SELECT Storage]: If this is activated, the storage structure is displayed in the selections where stock is selected. For example. under ‘Articles’. Activate, for better viewing, if you have a deep storage structure.

Additional costs [Materials]: Various articles (Additional costs). Used in connection with invoicing jobs (Service Management) and in connection with the invoicing of rented equipment (the lending/renting functionality).

Additional costs [Work]: Various articles hours/work. Used in connection with invoicing jobs (Service Management).

CostCarriers [Invoice/Hours]: Retrieving carriers on invoice lines and department on time registrations.

0 = Department from WO, Account from WO, Carrier from WO and Objective from WO.

1 = Department from employee, account from WO, Carrier from WO and objective from WO.

2 = Department from employee, account from Inventory, Carrier from WO and objective from WO.

3 = Department from employee, account from Accounting (Appendix set-up), Carrier from WO and Objective from WO.

4 = Department from WO, Account from Inventory, Carrier from WO and Objective from WO.

CostCarriers [Asset --> WO]: Cost carriers that are set up on an asset are inherited on work orders and history in accordance with whatever has been checked/activated in Department, Account, Carrier and Objective.

Reduce stock [WO/Checklists]: If this is activated, by default, on approval, ‘Reduce stock’ will be checked on the approval screen. Note that this setting does not affect the automatic stock draw when approving a checklist where the unit at the lubrication point has the same unit as the article connected to the lubrication point. Here, it is deducted from the storage regardless of whether it is activated or not.

Articles [For approval]: The system can be set up to require approval of new registered articles before they are put into use. Access to approval of new articles is set on the employee's user profile 17.0 Edit profile.

WO → Invoice [History]: If this is activated, invoices can be created for historical jobs (Service management).

Default unit: By default is set to pcs and whatever is used on articles. Can be overridden within the article.

Reservation of articles: This is where you set the number of weeks ahead that articles/parts that are planned for work orders should be reserved.

Transaction Cost: This is where you set which parts cost should be used on withdrawal transactions against work orders. 0 = uses the parts cost that is set for the part on the work order. 1 = uses the cost price that is set for the article in the article register. 2 = uses the cost price that is set for the article in the article register, and also updates this price on the work order.

Location treatment: This is where the default location treatment of the inventory directory is set (can be overridden within the individual inventory directory). Fixed - the article can only be placed in one location in the same inventory. Floating - the article can be placed in several locations in the same inventory. Note: only the default inventory directory is shown in the article list. Last = will always use the last location used, and here the article can also be placed in several locations in the same inventory.

...

Default unit: By default is set to pcs and whatever is used on articles. Can be overridden within the article.

Reservation of articles: This is where you set the number of weeks ahead that articles/parts that are planned for work orders should be reserved.

Transaction Cost: This is where you set which parts cost should be used on withdrawal transactions against work orders. 0 = uses the parts cost that is set for the part on the work order. 1 = uses the cost price that is set for the article in the article register. 2 = uses the cost price that is set for the article in the article register, and also updates this price on the work order.

Location treatment: This is where the default location treatment of the inventory directory is set (can be overridden within the individual inventory directory). Fixed - the article can only be placed in one location in the same inventory. Floating - the article can be placed in several locations in the same inventory. Note: only the default inventory directory is shown in the article list. Last = will always use the last location used, and here the article can also be placed in several locations in the same inventory.

Additional costs [Materials]: Various articles (Additional costs). Used in connection with invoicing jobs (Service Management) and in connection with the invoicing of rented equipment (the lending/renting functionality).

Additional costs [Work]: Various articles hours/work. Used in connection with invoicing jobs (Service Management).

WO → Invoice [History]: If this is activated, invoices can be created for historical jobs (Service management).

CostCarriers [Invoice/Hours]: Retrieving carriers on invoice lines and department on time registrations.

0 = Department from WO, Account from WO, Carrier from WO and Objective from WO.

1 = Department from employee, account from WO, Carrier from WO and objective from WO.

2 = Department from employee, account from Inventory, Carrier from WO and objective from WO.

3 = Department from employee, account from Accounting (Appendix set-up), Carrier from WO and Objective from WO.

4 = Department from WO, Account from Inventory, Carrier from WO and Objective from WO.

CostCarriers [Asset --> WO]: Cost carriers that are set up on an asset are inherited on work orders and history in accordance with whatever has been checked/activated in Department, Account, Carrier and Objective.

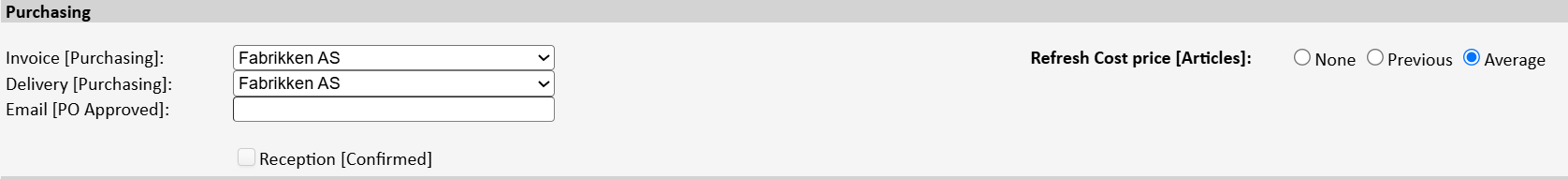

Invoice [Purchasing]: Default invoice address is taken from this addressee in the purchase order.

...